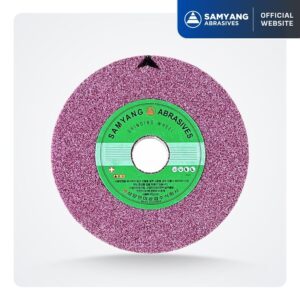

Surface Grinding Wheels

Call for Price

Surface Grinding Wheels

Call for Price

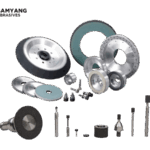

Toolroom Grinding Wheels

Call for Price

Toolroom Grinding Wheels

Call for Price

Toolroom Grinding Wheels

Call for Price

Toolroom Grinding Wheels

Call for Price

Surface Grinding Wheels

Call for Price

Surface Grinding Wheels

Call for Price

Vitrified wheels

Vitrified wheels Resinoid wheels

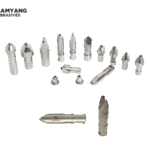

Resinoid wheels CBN/DIA

CBN/DIA Diamond Tools

Diamond Tools Other Grinding Wheels

Other Grinding Wheels